Anastase Minani

Bright and juicy, with toffee sweetness. Lemon, nectarine and black tea.

Since first meeting him in 2008, we’ve felt a deep respect and admiration for Dukunde Kawa Cooperative founding member and former president Anastase Minani. That’s why, we jumped at the opportunity to purchase his coffee when we first tasted it in 2017, and why we have continued to do so every year since.

Most of the coffees we source from Rwanda are traceable back to a washing station, or sometimes a farmer group. Most washing stations in Rwanda receive cherry from hundreds (and sometimes thousands) of farmers who own very small plots of land – on average less than a quarter hectare, with just 300-600 coffee trees. Separation of such tiny lots is expensive and impractical, so the large majority of coffees are processed as a mixed lot from multiple producers. Typically, lots are separated as day lots (ie. cherries that were all picked on the same day) rather than by a single farm or producer group.

Single producer microlots like this one are not very common in Rwanda. In this case, it is made possible due to the size of Minani’s farm, which is slightly larger than the average farm, totalling 1.3 hectares and around 3,000 trees. Minani also benefits from being a founding member of the Dukunde Kawa Cooperative, who have recognised the excellent agronomical practices he follows and consider him a role model to neighbouring farmers. Because the co-op also operate their own dry mill, they can process smaller lots individually, whilst minimising cost and maintaining excellent quality standards.

Anastase Minani has worked in coffee for over 50 years, having begun his career in 1970. He purchased his first plot of land in 1989, and decided to plant it with coffee trees and build a home there the following year. He started small, by planting coffee trees in his brother’s property nearby, and as the income he earned from coffee farming grew, so did his number of plots planted with the crop. He spent his early career providing agronomical advice in his community, in the sector of Coko, and saw firsthand how brokers were exploiting the local coffee farmers he would visit, as no cooperatives had yet been established in the area.

Selling coffee at the time was a challenge, because farmers had to process their own crop using hand pulpers or even stones to remove the cherry’s skin, and would prepare semi-washed (pulped natural) lots as they lacked the infrastructure to ferment and completely wash their parchment. These tiny lots would then be taken to Rwandan capital Kigali, where the prices offered were low because Rwandex, the country’s only exporter, had complete control of the supply chain. As a way to liberate himself and his neighbours from the brokers and traders they relied on, Anastase started an association with fellow growers in the region, to try to improve their position and enable them to negotiate a better price. As he recently explained of that decision, “I was the one who trained many farmers to grow, produce and process coffee well, and I was feeling the same struggle with them.“

Made up of 300 producers, the alliance soon became well-known in Kigali, because the quality of the coffee they produced was always high. In the early 2000s, following the Rwandan genocide and the introduction of the country’s first coffee cooperative (Maraba, in the Southern Province), the Defence Ministry approached the National Agricultural Export Development Board (NAEB), as they were looking for more potential groups to start another co-op. NAEB connected the ministry with Minani’s group, who received a $40,000 grant to establish Ruli washing station and the Dukunde Kawa Cooperative, becoming only the second co-op in the country.

Anastase was fully committed to the movement from the start, as he firmly believed that coffee had the power to improve the region’s economy. That’s why he donated the land where Ruli washing station was built on, including the plot of land that now homes the cooperative’s model farm (a former banana plantation that Minani cleared himself and replanted with coffee trees). Anastase also financed the construction of channeling that now brings water to the site, as it initially only supplied a local hospital. The first few years of the cooperative were focused on investing any income they earned into building a second washing station, Mbilima, to ensure contributing members who lived far away from Ruli would have a site that was closer and easier to access.

As the cooperative grew, Minani went on to serve as president between 2011 and 2017. During this time, he traveled with World Coffee Research founder Tim Schilling across the coffee-growing world to learn more about the best practices to follow and implement at Dukunde Kawa, and the coffee-consuming world to establish direct relationships with potential buyers. Under his leadership, the co-op thrived and became one of the most forward-thinking in Rwanda. While these years involved a lot of hard work and a significant financial commitment, Minani looks back at them fondly. As he told us on a recent visit, “When I see the progress of Dukunde Kawa, I know I did a good job. I feel fortunate to see so many farmers that are members now, and I’m also very grateful to you — for buying our coffee, and we hope to keep being the best for you and to keep our relationship into the future.”

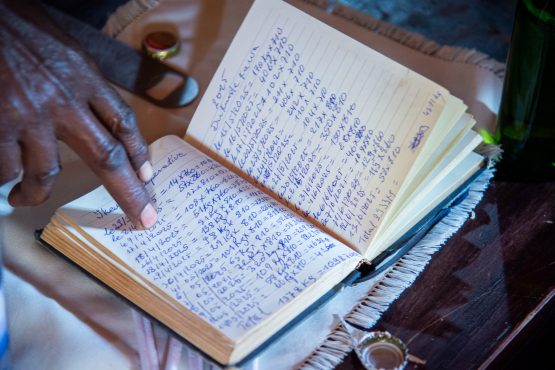

Today, Minani is one of Dukunde Kawa’s biggest producers and a role model to many. Known as a kind and generous man, Anastase always has a special set at the table of every cooperative celebration— with a bottle of his favourite beer included. He owns several patches of land in the Ruli Sector, where he grows around 3,000 coffee trees, and continues to plant seedlings for further expansions. Because different plots have trees of different ages, he is constantly renovating older patches of land, to ensure his income remains stable. Now that he is in his 70s, his goal is to plant seedlings closer to home, so that he can continue to oversee all farm activities with less effort. He remains as methodical as ever, however, keeping track of every sack of coffee cherry delivered for processing.

Because of his numerous plots, Anastase employs seven to ten people to help with the picking during the harvest. He no longer gets help from his eight children because they moved to Kigali to pursue university educations (which they have since accomplished), and have found careers in other occupations — something Anastase is immensely proud of. As he told us, “I’m among the few parents who have educated my kids. My family is united, from the eldest to the youngest: we are family, and that is my proudest achievement. One day a year, we do a ‘family day’ and we select a house where we’ll come together – from the 25 grandchildren, to my eight surviving children and me, and it lasts the whole day.”

Minani processes his coffee at nearby Ruli washing station. Given Minani’s proximity to the site, his farm is often used as a model farm to demonstrate the best approach for harvesting cherry, pruning trees and other agricultural practices to other cooperative members. He hopes that as Dukunde Kawa continues to grow and progress, every member can have the same positive and profitable experience he has had. When looking back at the co-op’s impact on the region, Anastase was firm in his belief that the job isn’t finished, telling us, “We believe that we are a model cooperative, and that other washing stations and cooperative should come to learn how collective group can work towards sustainable farming and business. That achievement is like opening the gates to the world. “

When we asked what his thoughts on the future of the cooperative were, Minani was equally adamant when he stated, “I think the most important thing in life is to be able to do what you love. I believe we need a new way of coffee farming where we can use the available land to increase productivity through innovation and creativity. And I believe that our children are having a better education than us. We are learning also new techniques of coffee farming through organic farming, using the compost and manure, so that the coffee productivity is increased but also the quality is improved and maintained. So the hope is still alive.”

As we were leaving his home, we asked if he had a message to anyone who enjoys his coffee in Australia, to which he replied, “I would like to say that the visit you do every year brings the connection so close and it’s so motivational and encouraging to keep grinding and keep on producing. And I feel proud that even my name is mentioned, and that my product is being served as my own entity.“

ABOUT RULI WASHING STATION

Ruli washing station was the first site established by Dukunde Kawa, back in 2003. It remains the main centre of operations for all of the cooperative’s activities, serving as the head office for the cooperative’s management team, who can often be seen buzzing about the property during the harvest.

In addition, the site is home to the Rambagirakawa Women Alliance’s community building and the newly-built Musasa Early Childhood Development Centre (Musasa ECDC), along with Dukunde Kawa’s cupping lab, nursery and model farm. Recently, the cooperative decided to expand their business by establishing a commercial roastery at Ruli, that supplies coffee to restaurants and hotels across town. Because the washing station is so central, Dukunde Kawa have also opened a café here, which sells the co-op’s coffee and locally baked goods. Recognising it has potential to service many members of the community, the cooperative is also hoping to establish their own bakery, to be run by youth who are part of the co-op.

Ruli is also where Dukunde Kawa’s dairy is located. Over the years, Dukunde Kawa have provided many of their member farmers access to their own cows, which are an important asset to a farming family. Culturally, they are seen as a symbol of wealth and status in Rwanda; practically, they provide milk and yoghurt to feed the family, produce excellent manure for the coffee farms, and create an opportunity for additional income. Having recently upgraded their largest pasteuriser from a 500L machine to one that can process 5,000L, Dukunde Kawa have been able to expand their operations at the dairy factory and take on a contract with a distributor who works throughout all of Rwanda and its neighbouring countries.

Over 2,000 farmers deliver cherry to the washing station throughout the season. Quality control at Ruli is overseen by Emerthe Mukamurigo, who has held this position since 2014, while day to day operations are managed by Philomene Nyirabantu, who has been a co-op member and part of Ruli’s full-time staff since 2004. In the twenty years she has been employed by the cooperative, Philomene has worked both as a drying officer at Ruli and as a field officer (she completed her studies as an agronomist in 2011), supporting member farmers in improving the quality and volume of their crop. Since 2022, Philomene has managed production at Ruli, earning the title of Station Manager in 2025.

During the harvest, Philomene is assisted by Dative Niyifasha, who supervises sorting and drying. There are a whopping 250 drying beds at Ruli, which require constant oversight. Dative has also been a cooperative and staff member since 2004, having transitioned from working with farmers on the field in 2017 to become a drying officer at Ruli. Both Philomene and Dative deliver coffee to be processed at Ruli and are members of the Rambagirakawa Women’s Alliance (Dative’s youngest is also a student at Musasa ECDC). The pair manage Ruli’s team with positivity and confidence — the pace at a processing site of this size can be relentless during the peak of the harvest — relying on their two decades of experience with Dukunde Kawa to continually encourage the washing station’s staff.

Ruli is Rainforest Alliance certified, UTZ certified, and Fair Trade certified. These certifications help the growing cooperative find different markets for the coffee. “We were already doing a lot of the things that were required for these certifications”, Isaac (the executive secretary of the cooperative at the time) explained, “We are always trying to be the best cooperative we can be. Getting the certifications has helped highlight what we are doing well and helped us raise our standards in other areas.”

Head here to learn more about the work of Dukunde Kawa in Rwanda.

PROCESSING AT RULI WASHING STATION

The team at Dukunde Kawa takes a huge amount of care in processing its coffee. All members of the cooperative are trained to only select ripe coffee cherries from their trees.

- On delivery, the cherries are inspected and sorted by hand to ensure only the very ripest cherries are processed. Farmers do the selecting, and receive the highest income from the ripest, healthier fruit. The remainder of their crop still gets purchased by the co-op, at a lower price, to be processed and sold for the internal market.

- Cherry is then sorted by weight using a Pinhalense machine, with any floaters are removed. By using a machine, rather than a clerk, Dukunde Kawa are more transparent with contributing growers about which fruit gets processed. Coffee is then depulped using a mechanical pulper that divides the beans into three grades by weight, with the heaviest, A1, usually having the highest cup quality.

- After pulping, the coffee is pre-washed, graded again using floatation channels that sort the coffee by weight, and left to ferment overnight for around 12–18 hours. The following day, wet parchment is the washed a second time and left to ferment for a further six hours — with the goal of removing as much mucilage as possible without using machinery that may accidentally crush or damage the beans.

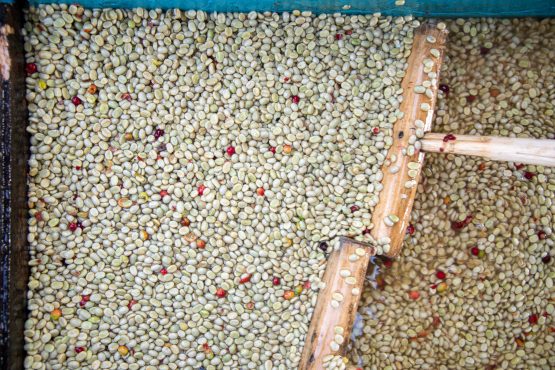

- As with most washing stations in Rwanda, women do the majority of hand-sorting. This takes place in two stages – on the covered pre-drying tables and on the drying tables. Washed beans are moved from the wet fermentation tanks onto the pre-drying tables, where they are intensively ‘wet sorted’ under shade for four hours. The idea is that greens (unripe beans) are still visible when the beans are damp, while the roofs over the tables protect the beans from the direct sunlight.

- Next, the beans are moved onto the washing station’s extensive raised drying tables for around two weeks, where they are sorted again for defects, turned regularly and protected from rain and the midday sun by covers, ensuring both even drying and the removal of any damaged or defective beans. During this period the coffee is also turned several times a day by hand to ensure the coffee dries evenly and consistently.

- After reaching 11-12% humidity, the coffee is then transported to Dukunde Kawa’s purpose-built warehouse prior to final dry milling and hand sorting at the cooperative’s milling facilities.

- Located in Ruli, Dukunde Kawa’s dry mill has the capacity to process one full container of coffee a day — and combines the use of technology with meticulous hand sorting to ensure only the best beans are bagged. Before being loaded for export, Rwanda’s National Agricultural Export Development Board also inspects and samples the prepped parchment.

WHY WE LOVE IT

It is very rare to be able to access a coffee that is traceable back to a single producer in Rwanda, so we feel extremely fortunate to be able to share this special lot from Anastase Minani. We first purchased Minani’s coffee 2017, when we also visited his farm for the first time. We have brought the very best of his crop each year since. We love this year’s coffee for its bright and juicy acidity, its notes of lemon, nectarine and black tea.