Cyarumbo Women’s Coffee

Green apple, grape and caramel. Lifted orange acidity with silky mouthfeel.

This special microlot was produced using coffee cherry from 97 female farmers who own and grow the crop on independent farms in the hills surrounding Cyarumbo washing station, in Rwanda’s Southern Province. The women are members of the Abizerwa Women’s Group, a women-led alliance within the Abahuzamugambi Ba Kawa Maraba Cooperative (or ‘Maraba’), one of Rwanda’s most highly respected coffee associations. In the local Kinyarwanda language, Abizerwa means “trusted people” – a fitting name for the group, given how much the members share support and resources with each other.

In collaboration with international buyers, Maraba has assisted the 758 members of Abizerwa in processing and marketing their coffees as separated ‘Women’s Coffee’ lots, which earns them an additional bonus payment on top of the quality premium all Maraba members receive. As the cooperative’s General Manager Theophile Biziyaremye explained during a recent visit, “While everything the cooperative does is first approved by the General Assembly, we started to have clients that requested women’s coffees. We started processing them separately because we had a market for them, and we made the efforts to reinforce and empower the project. After selling their coffee, the women receive the additional premiums from those particular customers — on top of the premiums they already receive for delivering high quality cherry.”

To distinguish their coffee and ensure it is processed separately, the women have organised to deliver cherry to the washing station on certain days of the week. All Abizerwa lots are kept separate through the processing, milling and preparation stages. This is made possible because Maraba owns and operates its own dry mill, allowing them to process smaller lots individually, whilst minimising cost and maintaining excellent quality standards.

On top of the coffee they grow, the members of Abizerwa collaborate on a number of other income-generating activities. These include the making of handicrafts, avocado cultivation, poultry farming, and more recently, beekeeping and soap making. Through these ventures, the women are diversifying their income sources, and in turn, increasing their total household earnings, which allows them to more easily cover expenses like their children’s education costs or renovations for their homes.

Because Abizerwa does not have a dedicated space to meet, the group’s members take turns hosting gatherings and workshops at their homes. Get-togethers always end up becoming community events, as the women connect and give each other encouragement while working on their various projects. Maraba hopes to build a space dedicated to Abizerwa’s work in the future, which will become necessary as the group’s numbers continue to grow thanks to the success they’ve found with specialty-focused international buyers like MCM.

Head here to learn more about the work of Maraba Cooperative.

ABOUT CYARUMBO WASHING STATION

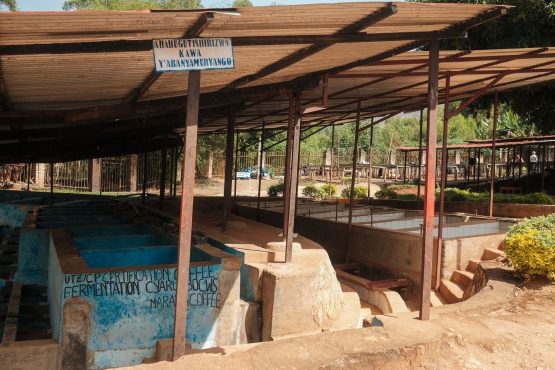

Visiting Maraba Cyarumbo is like stepping into Rwanda’s coffee producing history. Built in 2002, the washing station is the first specialty-focused facility to be established and operated by a cooperative, after the devastating 1994 genocide. Prior to Cyarumbo being built, most Rwandan farmers produced sun-dried natural coffees, or washed coffees that were pulped by hand using stones — with very few protocols for quality control. Transparency along the supply chain was non-existent, and farmers had no access to the international market or fair prices for their crop. Set up as a model operation, workers at Cyarumbo were key in developing and showcasing the best practices needed to maximise quality potential to the country’s ailing coffee industry. To say they were successful at this is an understatement, as Rwanda has gone to open over 300 washing stations since then!

On our most recent visit, we were greeted by beautiful singing from Cyarumbo’s team on our arrival. The songs were mostly in Kinyarwanda, and told the history of Maraba and of the role specialty coffee has played in re-building Rwanda’s economy. They also included some lyrics in English, which referenced the tasting notes Maraba coffee was known for, including descriptors like mango and chocolate. Clearly, staff and members have a deep connection to the co-op, and its heritage is a great source of pride for many growers in the Southern Province.

Cyarumbo washing station services nearly 600 members of the cooperative who deliver to the site and to nine other collection points in its vicinity. These include 13 individual farmer groups; six of which produce women lots, with another four focusing on youth coffees. Day to day operations overseen by the station manager, Aphrodice Twagirayesu, while Christine Ilibagiza serves as Head of QC. Because Christine cups every one of the cooperative’s lots, she plays an important role in directing the year’s production, as she gives station managers instructions to follow, to ensure everything Maraba processes is clean, transparent and rich in sweetness.

The washing station’s operations are in good hands under Aphrodice, whose contagious excitement and passion for specialty coffee boost the entire team’s morale during the busiest periods of the season. Aphrodice took on the role of manager at Cyarumbo in 2022, when he was just 30 years old, after completing a degree in agronomy. He first got involved with Maraba during his studies, when he completed an internship at the co-op as part of his education. Alongside his work during the harvest, Aphrodice receives training from Head of QC Christine, as his goal is to become well-versed in cupping himself. He also started farming his own coffee in 2024 and hopes to join the co-op as a member in the coming years, once his farm begins to produce coffee.

The area around Cyarumbo washing station has ideal growing conditions for exceptional coffee, with high elevations, good rainfall and steady, cool temperatures year-round. When driving through the region, colourful parcels of land growing all manner of food crops can be seen, as the soil here is incredibly fertile. Like most washing stations in Rwanda, Cyarumbo receives cherry from local farmers who tend to very small plots — often consisting of only a few hundred trees. These are then processed together as a mixed lot from multiple growers, and usually only separated as day lots (ie. cherries that were all picked on the same day). Producer group or single farm lots like this one are incredibly rare and very special, as separating them is often seen as expensive and impractical. The cooperative can do this efficiently at Cyarumbo, because the station processes cherry from Maraba members separately from non-members’ crop, using different-coloured fermentation tanks and carefully-labelled raised beds to ensure complete traceability.

Along with support during the harvest, Maraba also provide year-round agronomy workshops to all their members.This initiative is spearheaded by the co-op’s enterprising Head Agronomist Jean Baptiste Munezero, who instructs community leaders on the best practices needed to grow high quality cherry. They then share their learnings with their neighbours and friends. By creating a chain of information, Maraba is able to reach a wider audience without requiring many resources. Jean, or Bati, as he is known to friends and colleagues, is a banana farmer and the son of a coffee grower who delivers to Cyarumbo, and his role is crucial to Maraba’s success. Because he is responsible for ensuring farmers’ volumes increase, he is across all of Maraba’s yearly production and is in constant communication with washing station managers throughout the harvest.

As part of their commitment to quality and sustainability, Maraba cooperative has invested in upgrading the cherry sorting equipment and a water treatment facilities at each of their washing stations. They have also built a warehouse that is easily accessed from each of their processing sites, where parchment is safely stored before being transported to Kigali for final stages of milling and preparation for export. The complex will also soon feature a roastery and café to host visitors.

Head here to learn more about the work of Maraba Cooperative.

PROCESSING AT CYARUMBO WASHING STATION

The team at Cyarumbo Washing Station take a huge amount of care in sorting and processing their coffee. They own their own dry mill which enables them to control quality all the way through to export.

- Cherries are delivered to the washing station on the same day as they are picked and are inspected and sorted to ensure only the very ripest cherries are processed. They are then machine-sorted by density (and any floaters removed and returned to contributing farmer, to be sold at the local market) and pulped on the same day—always in the evening—using a mechanical pulper that divides the beans by weight (the heaviest usually being the best).

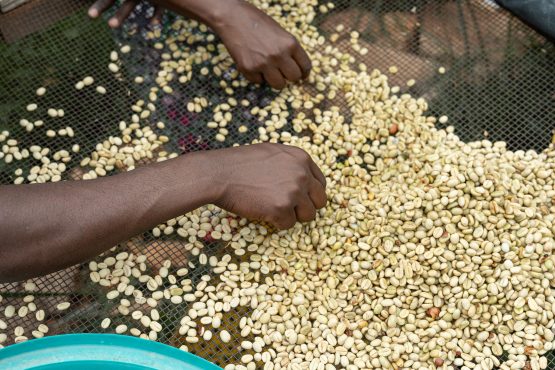

- After pulping, the coffee is fermented overnight for around 12–18 hours and checked regularly, to feel the stickiness of the remaining mucilage, as this determines when fermentation should stop. The beans are then washed with fresh water (sometimes up to five times) and moved to raised screens for ‘wet-sorting’ by hand.

- As with most washing stations in Rwanda, women do the majority of hand-sorting. This takes place in two stages—on the covered pre-drying tables and on the drying tables. Washed beans are moved from the wet fermentation tanks onto the pre-drying tables, where they are intensively sorted under shade for two days. The idea is that green (unripe) beans are still visible when they are damp, while the roofs over the tables protect the beans from the direct sunlight.

- Next, the beans are moved onto the washing station’s extensive raised beds for between 14-21 days, where they are sorted again for defects and turned regularly and protected from rain and the midday sun by covers, ensuring both even drying and the removal of any damaged or defective beans. During this period, the coffee is also turned several times a day by hand to ensure the coffee dries evenly and consistently.

- After reaching 11% humidity, the coffee is stored in parchment and then when adequately rested it is carefully processed at the cooperative’s brand-new dry mill in Huye.

WHY WE LOVE IT

We’re excited to offer this coffee, as it supports the women of Abizerwa who contribute to the Cyarumbo Washing Station. The group have ambitious, exciting goals for their future, and by buying their crop, we’re contributing to their success. Coffees from Huye District are also characterised by heavy sweetness and juicy character, which this lot exhibits in spades, along with a silky mouthfeel, green apple and grape in the cup.