Maraba Cooperative

In the local Kinyarwanda language, ‘Abahuzamugambi Ba Kawa’ means ‘Together we work the coffee’. The name is fitting, as the cooperative has played a key role in the rebuilding of Rwanda’s coffee industry.

Established in 2001, Abahuzamugambi Ba Kawa Maraba Cooperative (or ‘Maraba’) was one of the first cooperatives to be formed in the wake of the devastating 1994 genocide. It was formed with the purpose of increasing the viability of Rwanda’s coffee industry, by ensuring that members received a higher revenue for their coffee by selling coffee directly to exporters in Kigali, rather than through an intermediary agent. As it has evolved it has become a symbol of hope and progress in the coffee community, and has inspired the formation of many other specialty-focused cooperatives and coffee companies.

Maraba’s impact on Rwanda’s coffee industry is undeniable. In 2001, they were the country’s first cooperative to build a washing station, Cyarumbo. Set up as a model operation, every stage of production was considered and established in the best possible way. Despite being established in Maraba – which at the time was considered one of the poorest sectors in Rwanda – the model program was incredibly successful. Now, the cooperative owns and operates four washing stations in the Southern Province’s Huye and Nyamagabe districts: Kibingo, Kabuye, Cyarumbo and Sovu. These centralised washing stations allow farmer members to process and dry their coffee with meticulous care and attention, and to fulfil the potential for quality of the coffees that they grow.

The cooperative is currently led by President Lambert Mbayire and General Manager Theophile Biziyaremye. The dry mill and central offices are located in the Maraba Sector of the Southern Province’s district of Huye. Built in 2006, the dry mill was resourced and supported by the USAID-funded Partnership for Enhancing Agriculture in Rwanda through Linkages (PEARL) – much like Dukunde Kawa in 2000. Owning and operating a dry mill has been key in Maraba’s longevity: it has given members greater control over the quality of the coffee processed and has helped create jobs among the local community of the Huye District.

Since its formation, the cooperative has grown to encompass various communities of coffee growers in Rwanda’s Southern Province. Initially founded by just 20 growers, Maraba has grown to 1,508 members. Typically, members work on very small farms – averaging just a fifth of a hectare – and are situated around 1,700 meters above sea level. Maraba currently works with 37 different farmer groups, and an additional 23 women-only groups. Farmer and women-only groups have become very common and successful within Rwandan washing stations, as it allows members to process and market their coffees as a smaller, more selected lot.

Members pay an initial fee of 53,000 Rwandan francs (roughly $74AUD) to join the cooperative, followed by a smaller yearly fee that goes into a fund all members of Maraba benefit from. By becoming members, farmers are able to process their cherries centrally and combine their small, individual harvest into volumes that are large enough for export, boosting their earning potential considerably. Additionally, the cooperative also gives members a number of benefits, including financial support for school fees and health services, and access to a credit fund for home loans and farming equipment. This fund swelled over the 2022 harvest, providing member farmers with added access to funds and peace of mind for the off-season. Cooperative members also provide each other with invaluable support, by sharing resources and labour during the busy harvest period.

Because the cooperative is member-owned, all profits are divided between its members, or reinvested into shared infrastructure, resources and training. Maraba’s aim is to use the extra revenue to improve the yield and quality of their members’ coffee, which requires continued education and upgrading of equipment. The cooperative also provides members with access to organic pesticides at a discount and has recently begun making and distributing its own organic fertiliser. To encourage more sustainable farming practices, the cooperative regularly offers training for their members on ways to increase intercropping on their farms. Intercropping is key in making coffee-growing more viable, as it allows for edible crops and shade trees to be grown alongside coffee trees. Not only does this increase food security for farmers, but it also improves the quality of the coffee grown and the health of the soil.

HOW COFFEE AT MARABA IS PROCESSED

The team at Maraba Cooperative take a huge amount of care in sorting and processing their coffee. Because they own their own dry mill, they can control quality all the way through to export.

- Cherries are delivered to the washing station on the same day as they are picked and are inspected and sorted to ensure only the very ripest cherries are processed. They are then put into a floatation tank and sorted by weight (and any floaters removed) and pulped on the same day—almost always in the evening—using a mechanical pulper that divides the beans by weight (the heaviest usually being the best).

- After pulping, the coffee is fermented overnight for around 12–18 hours and then graded again using floatation channels that sort the coffee by weight. The beans are then soaked for a further 24 hours before being moved to raised screens for ‘wet-sorting’ by hand. All water used during the processing comes from a natural spring with water from the mountains.

- As with most washing stations in Rwanda, women do the majority of hand-sorting. This takes place in two stages—on the covered pre-drying tables and on the drying tables. Washed beans are moved from the wet fermentation tanks onto the pre-drying tables, where they are intensively sorted under shade for around six hours. The idea is that green (unripe) beans are still visible when they are damp, while the roofs over the tables protect the beans from the direct sunlight.

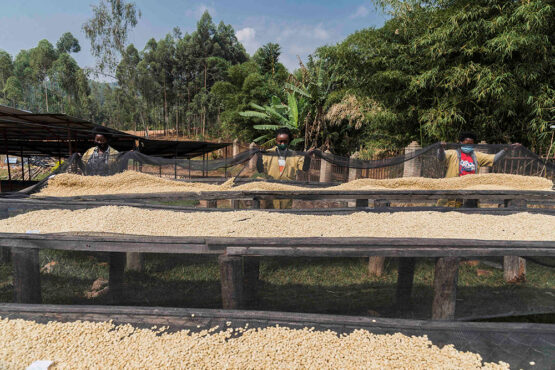

- Next, the beans are moved onto the washing station’s extensive raised drying tables (‘African Beds’) for around two weeks, where they are sorted again for defects, turned regularly and protected from rain and the midday sun by covers, ensuring both even drying and the removal of any damaged or defective beans. During this period, the coffee is also turned several times a day by hand to ensure the coffee dries evenly and consistently.

- After reaching 11% humidity, the coffee is stored in parchment and then when adequately rested it is carefully dry milled at the cooperative’s brand new dry mill in Huye.

LOOKING TO THE FUTURE

Investing in education is at the heart of Maraba Cooperative’s goal of promoting a viable coffee industry in Rwanda. They are currently in the process of certifying their washing stations as organic, as this will add value to the coffee they produce and encourage their members to continue following sustainable growing practices. The co-op has also begun investing in greenhouse drying facilities and are exploring a micro financing program to benefit their members. Both projects will be greatly beneficial to the cooperative’s members: the drying greenhouse will improve the longevity of the coffee Maraba produces; while the microfinance program will give members access to funds that can be used to improve conditions at their farms, with minimal risks.