Andre Hakizimana Organic

Orange marmalade, apricot and milk chocolate. Balanced and sweet, with great structure.

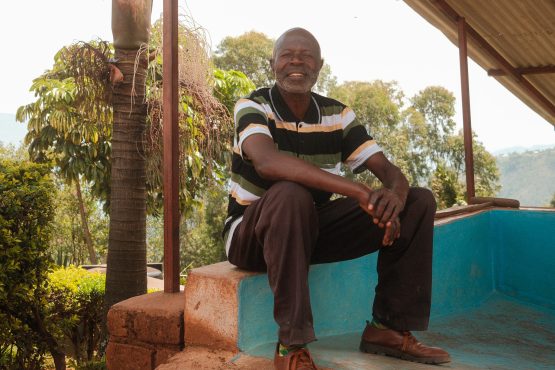

When we first met Andre Hakizimana in 2014, we were inspired by his boundless energy and enthusiasm, as he played a key role in many of Dukunde Kawa Cooperative’s operations. That’s why we were so excited when we first had the opportunity to buy his coffee in 2017, and why we have continued to do so every year since.

Andre has worked in coffee for over 40 years. He is one of the founding members of Dukunde Kawa Cooperative (his membership number is 35!) and remains very active in the cooperative – he’s often seen bounding up and down the hill that leads to Mbilima washing station during the off-season, to undertake maintenance and improvements outside of the harvest period. Andre’s career in coffee started when he left school at 15 and began working the fields with his father. He eventually inherited a plot of land, which he planted with coffee. An industrious coffee farmer, over time Hakizimana saved money and acquired more land to plant more trees. These efforts were, in part, to meet the needs of his growing family (Andre has five children), and he has used the income earned from coffee farming to pay for school fees, insurance, clothing and covering all the family’s needs.

Before the establishment of cooperatives and centralised washing stations, coffee production was extremely arduous for Rwandan coffee farmers. Processing was labour-intensive and lengthy, with very little equipment, training or resources available to rural farming communities. Coffee cherries were depulped by hand using stones and parchment was dried at farm level, before being sold to a middleman or ‘broker’ who would then on sell the coffee to traders or exporters based in Kigali. Not only did this result in a long and challenging harvest season for individual farmers, it also denied them any leverage for negotiating prices to achieve a fair and reliable income.

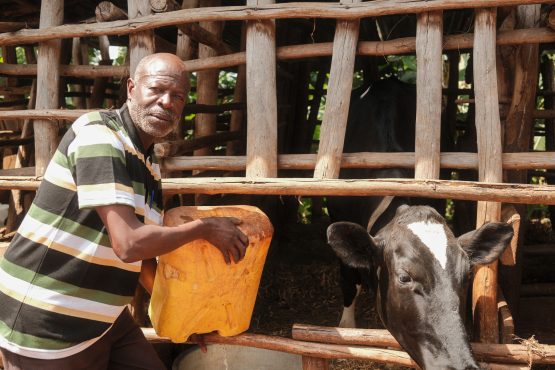

With the forming of cooperatives like Dukunde Kawa, farmers were able to access the support, education and resources necessary to adopt better farming practices, and processing moved to centralised washing stations – where shared infrastructure, equipment and adequate labour both minimised the workload for individuals and dramatically improved the coffee’s quality. Andre was an early joiner of Dukunde Kawa and has transformed his life since joining the cooperative. As he shared on a recent visit to his farm, “[Thanks to] the way Dukunde Kawa has processed and marketed our production, the price has improved significantly. The cooperative pays us regularly, provides us with insurance and bonuses, and even with cows. Now there is a lot less work to do, and only during the harvest, because Dukunde Kawa does the rest.”

Today, Andre and wife, Anathal Mukawiza, own over 3,000 coffee trees and produce around seventy tonnes of coffee per season, making them one of Dukunde Kawa’s largest producing members. Their production has grown so much that Andre now employs up to 15 workers during the harvest to help him with cherry selection. The pickers are trained to select only the ripest fruit for harvest and do several passes throughout the season to ensure quality standards are met. Andre continues to increase his arable land and add more trees, to ensure annual production remains stable, even if a plot or two drops volume due to unforeseen circumstances or climate events.

Coffee is at the centre of Andre’s life, and every time we visit, he is excited to give us a tour of his farm and talk about the ongoing harvest. Located at high elevations in a uniquely cool and humid microclimate, the farm experiences perennial rainfall, meaning there is cherry on the trees that must be harvested and processed year-round. Mbilima washing station only operates and receives cherry during Rwanda’s main harvest — outside of those times, the couple must sell their cherry to a local broker who processes at a small scale and sells parchment for consumption in the internal market. The Rwandan government prohibits the installation of wet mills at farm levels to discourage farmers from processing at home (and potentially lowering the overall quality of Rwandan coffee), so the pulping is done by hand using stones.

Like all farmers who deliver to Mbilima, Andre farms 100% organically. He uses manure from his farm animals to fertilise his trees and has planted squash, pumpkins and banana trees to prevent erosion and keep the soil moist, and also grows a local variety of yellow chilli, red beans and tomatoes for consumption. His land is so fertile that he often has to sell or give away his produce, as the family can’t go through it all in time. Anathal works closely with him on the farm and the couple take great pride in their work and their coffee, which they see as an important investment in their family’s future. He hopes his children will follow in his footsteps, and has recently gifted 50 coffee trees to each of his four children who are still studying and a plot of land with 150 trees to his married daughter. After living on the property for nearly 40 years, Andre has been renovating the homestead, using the income generated from coffee sales to pay for it.

When we asked Andre what makes him proudest about working in coffee, he shared: “[The fact] that I have my own home, I have managed to buy a motorbike… I live off my own work.” The motorbike helps Hakizimana in his role as dairy and site collector for Dukunde Kawa. By taking on this extra work, Andre helps his neighbours deliver cherry to Mbilima washing station and their milk to Ruli, where it is processed at Dukunde Kawa’s plant. Whilst Andre uses his own resources to transport the produce, he also receives an extra premium from the co-op, to compensate and reward his efforts.

On our most recent visit, we were delighted to see how much Andre’s farm had recovered, following hail storm damage in 2023. While most of his plots were affected, they have since come back to full health. When we asked Hakizimana where he found the energy to persevere with coffee after such a devastating weather event, he told us, “That’s bravery I learned from my father. He was so brave and a good coffee farmer. I inherited my coffee farming spirit from our family. The motivation also comes from the revenues and income that we receive from coffee, and the business and the impact that we are making in our family house.”

ABOUT MBILIMA WASHING STATION

Mbilima is nestled in the high hills near the small town of Musasa, located in the Coko Sector of Gakenke District, in Rwanda’s rugged and mountainous Northern Province. Typically, farms in this area are very small – averaging just a quarter of a hectare – and are situated between 1,800 to 2,100 meters above sea level. Coffee is grown as a cash crop, alongside subsistence food crops like maize, beans and sorghum and some livestock like goats, chickens and sometimes cows.

Mbilima was built in 2005 with the profits earned from the cooperative’s first washing station, Ruli. The site sits at a staggeringly high 2,070 metres above sea level, making it Dukunde Kawa’s highest washing station. By Rwandan standards, Mbilima is a fairly small washing station, yet they always produce exceptional coffee thanks to their dedicated team (which is mostly made up of women). Day-to-day operations at Mbilima are overseen by Jean Bosco himself, who began working at the site when it was being constructed in 2004 and has been the washing station’s manager since 2012, while QC is headed by Agnes Mushimiyimana.

Mbilima washing station is 100% organic, Rainforest Alliance certified, UTZ certified, and Fair Trade certified. Jean Bosco explained that becoming certified was extremely useful in formalising and documenting a lot of things that the cooperative was already doing. “It helped us to better the lives of our producers and quality of our coffee. It’ was a lot of work to get the certifications,” he explained, “but it also made us realise how many positive things we were already doing. The certifications reinforce this.” Because all lots processed at Mbilima are organic, they are dry milled and stored separately.

While the site received organic certification in 2018, the lengthy process began in 2015. Dukunde Kawa wanted to operate one of their washing stations using organic practices and, after consulting with local farmers, they decided on Mbilima. The transition required a lot of work and created challenges for farmers, who initially experienced decreased yields after they stopped using synthetic fertilisers. After a couple of years, however, they began to realise that while volumes stayed the same, their trees were significantly healthier after the harvest (whereas under synthetic fertilisation, they would wither and “dry up” after cherry was picked) — leading to greater stability in the crop produced.

The farmers who deliver to Mbilima are now firm believers in the benefits of organic production and certification. Certification is free for the producer, with Dukunde Kawa covering all costs associated with the program (including surveyors who inspect participating farms on regular intervals), and paying an additional premium for these coffees. By committing to the program, farmers must cease all use of synthetic fertiliser — not just from coffee plots, but from the entire farm — a transition that Dukunde Kawa supports by sending trainers to the farms and providing further education. Since the co-op first launched the initiative, the number of enrolled producers has grown by nearly 25% — proof that in the long run, the benefits outweigh the initial difficulties experienced.

Site manager Jean Bosco has personally seen the benefits of organic farming at his own plot of land, as he also grows coffee and delivers to Mbilima. On our most recent trip to the region, we stopped by Habimana’s home, where he lives with wife Emerthe and his four children. Walking up to the property we first saw the couple’s beautiful front garden, which includes a few coffee trees, along with pumpkin and squash (which also provide excellent ground cover) for consumption and herbs that are used in the kitchen. Jean Bosco was thrilled to hear how much coffees processed at Mbilima were enjoyed in Australia, and assured us that “coffee will be still here, we will keep producing good quality and good volume for you. And we are happy that they are appreciating the quality that we are serving them.”

Head here to learn more about the work of Dukunde Kawa in Rwanda.

PROCESSING AT MBILIMA WASHING STATION

The team at Dukunde Kawa takes a huge amount of care in processing its coffee. All members of the cooperative are trained to only select ripe coffee cherries from their trees.

- On delivery, the cherries are inspected and sorted by hand to ensure only the very ripest cherries are processed. Farmers do the selecting, and receive the highest income from the ripest, healthier fruit. The remainder of their crop still gets purchased by the co-op, at a lower price, to be processed and sold for the internal market.

- Cherry is then sorted by weight using a Pinhalense machine, with any floaters are removed. By using a machine, rather than a clerk, Dukunde Kawa are more transparent with contributing growers about which fruit gets processed. Coffee is then depulped using a mechanical pulper that divides the beans into three grades by weight, with the heaviest, A1, usually having the highest cup quality.

- After pulping, the coffee is pre-washed, graded again using floatation channels that sort the coffee by weight, and left to ferment overnight for around 12–18 hours. The following day, wet parchment is the washed a second time and left to ferment for a further six hours — with the goal of removing as much mucilage as possible without using machinery that may accidentally crush or damage the beans. As with most washing stations in Rwanda, women do the majority of hand-sorting. This takes place in two stages – on the covered pre-drying tables and on the drying tables. Washed beans are moved from the wet fermentation tanks onto the pre-drying tables, where they are intensively ‘wet sorted’ under shade for four hours. The idea is that greens (unripe beans) are still visible when the beans are damp, while the roofs over the tables protect the beans from the direct sunlight.

- Next, the beans are moved onto the washing station’s raised drying tables for around two weeks, where they are sorted again for defects, turned regularly and protected from rain and the midday sun by covers, ensuring both even drying and the removal of any damaged or defective beans. During this period the coffee is also turned several times a day by hand to ensure the coffee dries evenly and consistently.

- After reaching 11-12% humidity, the coffee is then transported to Dukunde Kawa’s purpose-built warehouse prior to final dry milling and hand sorting at the cooperative’s milling facilities.

- Located in Ruli, Dukunde Kawa’s dry mill has the capacity to process one full container of coffee a day — and combines the use of technology with meticulous hand sorting to ensure only the best beans are bagged. Before being loaded for export, Rwanda’s National Agricultural Export Development Board also inspects and samples the prepped parchment.

WHY WE LOVE IT

Most of the coffees we source from Rwanda are traceable back to a washing station, or sometimes a farmer group. Typically, washing stations in Rwanda receive cherry from hundreds (and sometimes thousands) of farmers who own very small plots of land – on average less than a quarter hectare, with just 300-600 coffee trees. Separation of such tiny lots is expensive and impractical, so the large majority of coffees are processed as a mixed lot from multiple producers. Typically, lots are separated as day lots (ie. cherries that were all picked on the same day) rather than by a single farm or producer group.

Single producer microlots like this one are not very common in Rwanda. In this case, it is made possible due to the size of Andre and Anathal’s farm, which totals 1.3 hectare and includes over 3,000 coffee trees. Andre also benefits from being a member of the Dukunde Kawa Cooperative, who have recognised the excellent agronomical practices he follows and consider him a role model to neighbouring farmers. Because the co-op also operate their own dry mill, they can process smaller lots individually, whilst minimising cost and maintaining excellent quality standards. We have known Andre for many years, and have loved the floral, delicate profile of the coffee he produces from the first time we cupped it in 2017.