Nyamagabe

Juicy and sweet, with strawberry lemonade, kumquat and black tea. Great texture and balance.

This 100% Red Bourbon lot was produced at Remera washing station, using cherries grown by independent smallholder producers who farm coffee in the region’s high hills. Established in 2007, Remera is located in the Kigoma Sector of Huye District, in Rwanda’s rugged Southern Province, and is the largest of partner Buf Coffee’s washing stations.

Typically, farms in the area surrounding Remera are very small – averaging around a quarter of a hectare (or 300-600 trees) – and are situated between 1,750 to 2,100 meters above sea level. The high elevation of the surrounding area allows coffee cherry to ripen slowly, resulting in a complex and sweet flavour profile. Coffee is grown as a cash crop, alongside subsistence food crops like maize, beans and sorghum and some livestock like goats and chickens. Cows are also an important asset to a farming family. Besides having practical advantages – like providing milk and yoghurt to feed the family, producing excellent manure for the coffee farms, and being an opportunity for additional income – they are also a traditional symbol of wealth and status in Rwanda.

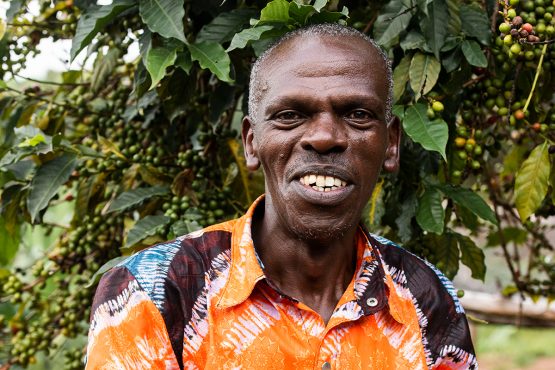

Remera washing station services about 700 local coffee farmers in total. The washing station sits at 1,953 meters above sea level, on mineral-rich soil and a lush environment that is well suited to specialty coffee production. Day-to-day operations at Remera are overseen by station manager, Alexis Dushimimana, who is assisted by Head of Quality Control, Esther Ingabire. Together, they ensure that the coffee is harvested and processed with care and that production standards are kept at the highest possible level. Remera typically provides jobs for 60-80 seasonal workers during the peak harvest and staffs seven permanent positions. At the end of each season, any surplus profits are shared with the producers and washing station managers.

Head here to learn more about the work of Buf Coffee in Rwanda.

HOW COFFEE IS PROCESSED AT REMERA WASHING STATION

- The ripe cherries are picked by hand and then delivered to the washing station either on foot, by bike, or by trucks that pick up cherries from various pick-up points in the area.

- Before being pulped, the cherries are deposited into flotation tanks, where a net is used to skim off the floaters (less dense, lower grade cherries). The heavier cherries are then pulped the same day using a mechanical pulper that divides the beans into three grades by weight.

- The beans (in parchment) are then dry-fermented (in a tank with no added water) overnight for 8–12 hours. They are then sorted again using grading channels; water is sent through the channels and the lighter (i.e. lower grade) beans are washed to the bottom, while the heavier cherries remain at the top of the channel.

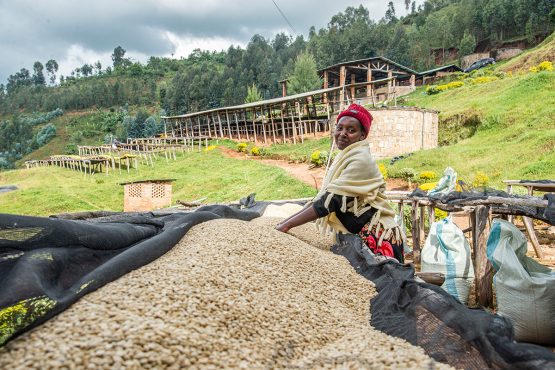

- The wet parchment is then soaked in water for around 24 hours, before being moved to pre-drying beds where they are intensively sorted for around six hours. This step is always done while the beans are still damp because the green (unripe) beans are easier to see. It is also always done in the shade to protect the beans from direct sunlight (which they have found helps to keep the parchment intact and therefore protects the bean better).

- The sorted beans are finally moved onto raised African drying beds in the direct sun to dry slowly over 10–20 days. During this time the coffee is sorted carefully for defects and turned regularly to ensure the coffee dries evenly. It is also covered in the middle of the day when the sun is at its hottest.

- Once at 11–12% humidity, the coffee (still in its parchment) is stored in the washing station’s warehouse in carefully labelled lots until it is ready for export. The coffee is then sent to Buf’s dry mill, Ubumwe (built 2017), to be dry-milled. Here the parchment is removed, and the beans are sorted again by hand and using machinery to remove any physical defects. This is done under the watchful eye of Edouine Mugisha, who has worked with Buf since 2011. Having control over the milling of the coffee means that Buf has greater control over the quality of sorting and processing from cherry delivery right through to export.

WHY WE LOVE IT

We have been buying from Remera since our very earliest days as MCM, and love featuring coffees from this washing station each year. We think this lot provides exceptional value, and is well suited to many applications. We love its sugary sweetness, dark chocolate and red fruit character.