Remera Twitezimbere

Bright, tropical acidity, with pineapple, lime and green grape, balanced by golden syrup sweetness. Juicy and distinct.

This microlot was produced by around 32 small holder producers who farm coffee in the high hills surrounding Remera washing station, located in the Gaseke Sector of Nyamagabe District, in Rwanda’s Southern Province. The farmers are members of the Twitezimbere Farmers’ Group, a small association of producers who deliver coffee to Buf Coffee company, who own and manage Remera along with three other washing stations.

Most washing stations in Rwanda receive cherry from hundreds (and sometimes thousands) of farmers who own very small plots of land. Separation of such tiny lots is expensive and impractical, so the large majority of coffees are processed as a mixed lot from multiple producers. Typically, lots are separated as day lots (ie. cherries that were all picked on the same day) rather than by a single farm or producer group.

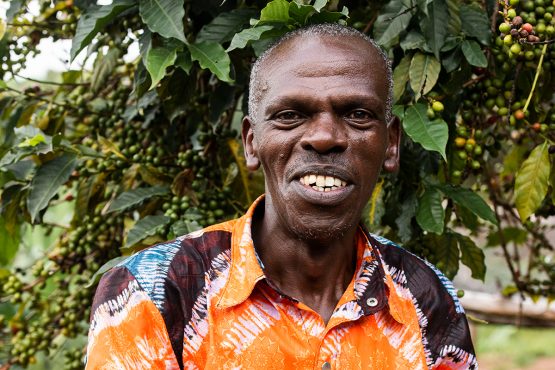

The farmers who make up the Twitezimbere group come from the nearby village of Nyabubare. Recently, they formed an association to process and market their coffees separately as a smaller, more selected lot. The group also provide each other with invaluable support, by sharing resources and labour during the busy harvest period. They named their association Twitezimbere, which roughly translates to ‘we work together for development’ in the local Kinyarwanda language.

To distinguish their coffee and ensure it is processed separately, the producers have organised to deliver cherry to the washing station on certain days of the week. Selling their coffee as a separate lot allows them to directly benefit from any higher prices paid specifically for their coffees (rather than these profits being shared equally amongst all contributing producers) and results in a higher income to support their families. This creates an effective incentive for the farmers to work as a collective towards achieving the very best quality, and we think the results are evident in the complex and clean profile of their coffee!

ABOUT REMERA WASHING STATION

This coffee was processed at Remera washing station, which was established in 2007 and is the largest of Buf’s washing stations, servicing about 700 local coffee farmers. The washing station sits at 1,953 meters above sea level in the high, rugged mountains of Rwanda’s Southern Province. The area surrounding the washing station has mineral-rich soil and a lush environment that is well suited to specialty coffee production.

Quality control and day-to-day operations at Remera are overseen by station manager, Alexis Dushimimana, who is assisted by Head of Quality Control, Esther Ingabire. Together, they ensure that the coffee is harvested and processed with care and that production standards are kept at the highest possible level. Remera typically provides jobs for 60-80 seasonal workers during the peak harvest and staffs seven permanent positions. At the end of each season, any surplus profits are shared with the producers and washing station managers.

Head here to learn more about the work of Buf Coffee in Rwanda.

HOW COFFEE IS PROCESSED AT REMERA WASHING STATION

- The ripe cherries are picked by hand and then delivered to the washing station either on foot, by bike, or by trucks that pick up cherries from various pick-up points in the area.

- Before being pulped, the cherries are deposited into flotation tanks, where a net is used to skim off the floaters (less dense, lower grade cherries). The heavier cherries are then pulped the same day using a mechanical pulper that divides the beans into three grades by weight.

- The beans (in parchment) are then dry-fermented (in a tank with no added water) overnight for 8–12 hours. They are then sorted again using grading channels; water is sent through the channels and the lighter (i.e. lower grade) beans are washed to the bottom, while the heavier cherries remain at the top of the channel.

- The wet parchment is then soaked in water for around 24 hours, before being moved to pre-drying beds where they are intensively sorted for around six hours. This step is always done while the beans are still damp because the green (unripe) beans are easier to see. It is also always done in the shade to protect the beans from direct sunlight (which they have found helps to keep the parchment intact and therefore protects the bean better).

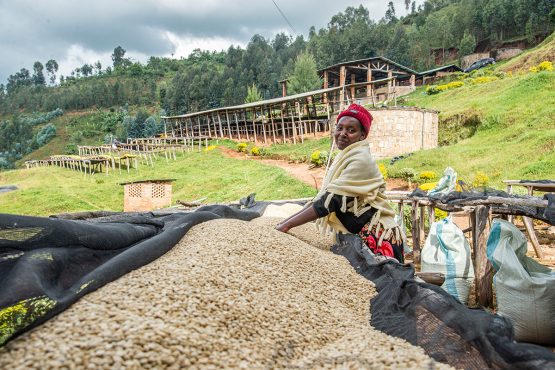

- The sorted beans are finally moved onto raised African drying beds in the direct sun to dry slowly over 10–20 days. During this time the coffee is sorted carefully for defects and turned regularly to ensure the coffee dries evenly. It is also covered in the middle of the day when the sun is at its hottest.

- Once at 11–12% humidity, the coffee (still in its parchment) is stored in the washing station’s warehouse in carefully labelled lots until it is ready for export. The coffee is then sent to Buf’s dry mill, Ubumwe (built 2017), to be dry-milled. Here the parchment is removed, and the beans are sorted again by hand and using machinery to remove any physical defects. This is done under the watchful eye of Edouine Mugisha, who has worked with Buf since 2011. Having control over the milling of the coffee means that Buf has greater control over the quality of sorting and processing from cherry delivery right through to export.

Rachel Uwamaliya, carefully sorting coffee in the sun and turning it regularly to ensure it dries evenly. Chantal Nyiraneza, carefully sorting coffee in the sun and turning it regularly to ensure it dries evenly. Angelique Uwase, carefully sorting coffee in the sun and turning it regularly to ensure it dries evenly.

WHY WE LOVE IT

We’re excited to purchase coffee from Twitezimbere Farmers’ Group for a fourth year, and to support the farmers of Nyabubare Village.