Don Carlos Coco Natural

Distinct, winey acidity balanced by panela sugar. Tamarind, yellow plum and pineapple jam.

This very special 100% Caturra microlot comes from a farm called Don Carlos owned by Pedro Rodríguez and his family. Over the last decade, under the banner of Agricafe, the Rodríguez family have worked tirelessly to build the production of and market for Bolivian specialty coffee, helping hundreds of local farmers recognise and realise the potential of their land and crops.

Don Carlos is located in the colonia of Bolinda, which lies in a lush, steep mountain valley around 10 kilometres outside of the town of Caranavi. The colonia of Bolinda was founded 52 years ago and was once known as ‘Bolivia Linda’ or ‘Beautiful Bolivia’. Over the years this name was shortened to Bolinda, and it is now one of the larger settlements in the area.

Like all other Rodriguez farms, Don Carlos is meticulously organised, and ituated at 1,546–1,650m above sea level. The estate is just over 18 hectares in total, of which just over one-third is under production.

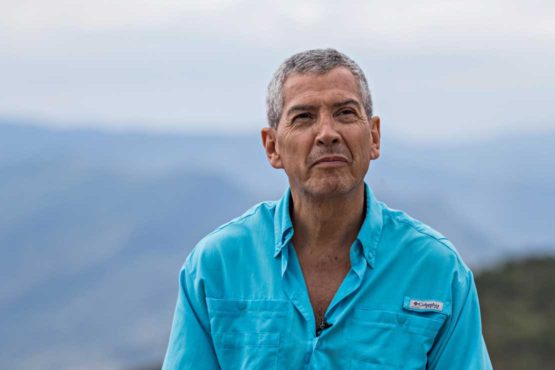

Established in 2013, Don Carlos is the second farm the Rodríguez family has planted, and they used the learnings from their first farm, La Linda, to make informed decisions on how to plant and manage the it. This farm is named after one of Agricafe’s longest-standing employees, Don Carlos Mariaca, who has worked with Pedro Rodriguez, Agricafe’s founder, for nearly three decades. Don Carlos and Pedro Rodriguez were together when specialty coffee began to be produced in Bolivia.

With help from Don Carlos, Pedro built a wet mill to process coffee in Caranavi. He then helped Pedro encourage local producers to deliver their coffee to the mill and and began educating them about the importance of selectively handpicking their cherries. Soon Agricafe was processing small micro-lots from many small local producers, and the results were outstanding, thanks to the unique combination of heirloom varieties, rich soil, and incredibly high altitudes. Don Carlos also provided invaluable advice and encouragement and ultimately convinced the Rodríguez family that buying the land to produce their own coffee was a good idea.

Thanks to his ties to the Caranavi community, Don Carlos has since transitioned from agricultural work to more closely representing Agricafe with local farmers. He has liaised with the local government to raise funds for social projects, earning him the respect of the town. In his work for Agricafe, Don Carlos spends much of his time confirming all Caranavi Los Rodríguez farms are safe workspaces, and talking to smallholder producers who sell cherry to Agricafe, to ensure their water needs are met and that their children are attending school.

ABOUT CARANAVI

The inhabitants of Caranavi first started farming coffee in the 1950s, when a government-led agrarian reform resulted in small parcels of land (of around 10 hectares in size each) being redistributed back to thousands of largely Aymara families. The Aymara are one of Bolivia’s 36 indigenous nations, who originally lived on the highlands of the Altiplano (a vast plateau of the central Andes that stretches from southern Peru to Bolivia and into northern Chile and Argentina). Along with the Quechuas, who lived in the Bolivian lowlands, both groups immigrated to Caranavi to find a better life through agriculture.

The municipality is located in the Yungas ecoregion, one of South America’s most fertile and diverse locations. The region runs along both sides of the Andes Mountains, and is known for the world’s highest lake, called Titicaca. In the Quechua language, Yungas translates to “the warm lands,” in reference to the rainy, yet warm climate experienced in the region.

HOW THIS COFFEE WAS PROCESSED

At Don Carlos, pickers from the Villa Rosario community and the state of Beni are hired to carefully handpick the coffee during the harvest. These pickers are hired by Elda and her husband Felix (Carmela Aduviri‘s son), and trained to collect only the very ripest cherries, and multiple passes are made through the farm throughout the harvest to ensure the coffee is picked at its prime. Selective picking is extremely important for special micro-lots like this one, to ensure the sweetest cup. The Rodríguez family has found that harvesting the very ripest (almost purple) cherries result in the most complexity and distinction in the coffee.

Pedro draws a lot of inspiration from the wine industry in his approach to coffee production, and is always innovating and trialling different processing techniques. This lot was processed with experimental techniques, part of the Rodriguez’ family’s long term strategy to achieve the greatest distinction and diversity in their special lots. As Pedro’s daughter, Daniela shares: “We’re keeping a registry of all the data we’re compiling, to use in the coming seasons. It includes information on the types of tanks used, bacteria and yeast activity, ambient temperature and weather conditions… we’re working hard to identify the ideal processing conditions for each variety and farm.” Watch the video below, to see how this coffee was processed:

Cherries for this lot were delivered to Agricafe’s state of the art mill Buena Vista in the evening. After being inspected and weighed, the coffee cherry was carefully sorted by weight using water, and floaters were removed. Following this, the coffee was placed on a conveyor belt and disinfected, in a similar process used for wine grapes. It was then carefully washed and laid out to dry on patio for 48-72 hours, before being placed in one of Buena Vista’s ‘stationary box’ (or coco) dryers, until it reached 11.5% humidity.

These boxes are series of steel containers that are typically used for drying cocoa pods. They use a gentle flow of warm air from below the coffee bed to dry the parchment slowly and evenly. Coffee was stirred manually at regular intervals to further ensure it dried at a uniform rate.

Once the coffee was dry, it was transported to La Paz where it was rested before being milled at Agricafe’s dry mill, La Luna. At this state-of-the-art mill the coffee was first hulled and sorted using machinery, and then by a team of workers who meticulously sorted the coffee by hand under UV and natural light. The mill is one of the cleanest and most impressive we have seen – you can read more about it here.