Michel Dusengimana

Rich, caramel sweetness with apricot jam and golden raisin. Well-structured and complex.

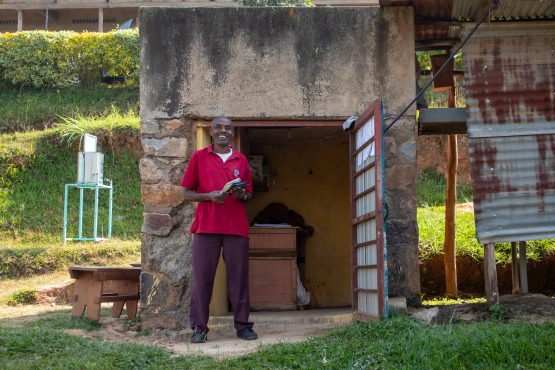

As one of Dukunde Kawa’s founding members and longest serving washing station managers, we’ve known Michel Dusengimana for many years. Every time we visit Nkara, the site he manages, he is incredibly friendly and generous with his time, which is why we’re excited to offer coffee from his and wife Devotha Nyirahabimana’s farm for the very first time.

As one of the original farmer members of the cooperative, Michel Dusengimana is fully committed to the work of Dukunde Kawa. He began his coffee career at 15, when he planted his first plot after being inspired by his parents and the hope that coffee farming could earn him a good income. Michel has since expanded into three plots, and built a house (complete with solar panels and running water), where he lives with Devotha and their three sons. He began full-time employment at the co-op in 2004, as a machine operator at Ruli washing station, where he processed the cooperative’s first batch of coffee cherries. When the building of Nkara was completed and production large enough to need a full-time station manager, Michel was eager to take the role on. Nearly twenty years later, Dusengimana remains as enthusiastic as ever, leading his them with great care and respect.

Life for Michel becomes incredibly busy during the harvest, because he spends increasingly long hours at Nkara as the season peaks, while Devotha tends to the farm, with help from their children. Yet, Michel’s cheerful and calm spirit doesn’t falter, even after having just finished the washing station’s busiest harvest. When we asked Michel how he remained so motivated after so many years in the job, his response was pragmatic and insightful, “The more good coffee you produce, the more money you can earn. When you have an ongoing revenue, you can respond to any need and develop together with your family. Coffee is the best cash provider out of any other crops grown here.” Weeding is done throughout the year, with all mulching and fertilising (using manure from the family cow and chickens) done by hand. On the property, the family also grow beans and maize — both for their own consumption and to sell at the local market.

Outside of coffee, Michel has established a successful poultry business. The family keep 30 chickens, and Michel is able to sell eggs locally thanks to his trusty motorcycle, which he was able to purchase with the profits earned from the sale of his coffee. His goal is to expand to a total of 60 chickens, which would double his production, and would provide the family with greater financial security by diversifying his income.

ABOUT NKARA WASHING STATION

The picturesque Nkara is Dukunde Kawa Cooperative’s smallest and most remote washing station. Sitting in a valley at 1,880 meters above sea level, the site overlooks a beautiful landscape of rolling green hills dotted with farms and forests.

Unlike most coffee-producing countries, where land size is used as a measure of scale, farms in Rwanda are often very small, and production capability is determined by the number of trees a farmer tends to. The majority of producers who contribute to the Nkara washing station own a couple of hundred trees, planted on one tenth of a hectare of land, along with subsistence food crops like maize, beans and sorghum and livestock like cows, goats and chickens.

Established in 2007, Nkara is the third and final washing station built by Dukunde Kawa Cooperative. Day to day operations are overseen by Michel Dusengimana, who has been the manager since the start, while quality control operations are overseen by Emerthe Mukamurigo. As one of the original farmer members of the cooperative, Michel is fully committed to the work of Dukunde Kawa. He began full-time employment at the co-op in 2004, as a machine operator at Ruli washing station, where he processed the cooperative’s first batch of coffee cherries. When the building of Nkara was completed and production large enough to need a full-time station manager, Michel was eager to take the role on, and nearly twenty years later, he remains as enthusiastic as ever.

While Michel’s team may not be as large as those in Dukunde Kawa’s other washing stations, he leads them with great care and respect. During the harvest, cherries begin to be delivered as early as 10AM, to be processed from 6PM onwards. On our most recent visit, we asked Michel how he keeps staff motivated, particularly during the season’s busiest periods, to which he replied, “One of the things I do, is I respect their time, so they always know the day’s starting point and ending time. This way no one has to overstay or do extra hours, and everyone can go home on time to live their lives.” When we then asked Michel how he remained so motivated after so many years in the job, his response was pragmatic and insightful, “The more good coffee you produce, the more money you can earn. When you have an ongoing revenue, you can respond to any need and develop together with your family. Coffee is the best cash provider out of any other crops grown here.” For the future of Nkara, Michel hopes to continue to see improvements. “We want to expand our production capacity and renovate the infrastructure, so we can keep producing good coffee,” he told us with a smile.

As a contributor to Nkara himself, Michel is happy to advocate for the agronomical advice offered by Dukunde Kawa with his neighbours and friends. While historically many farmers in the region have grown coffee as a monoculture on its own plot, in recent years the cooperative has begun to encourage practices that promote a richer biodiversity. This includes the planting of shade trees to protect the plants’ foliage, and squash to provide cover for the soil.

Head here to learn more about the work of Dukunde Kawa in Rwanda.

PROCESSING AT NKARA WASHING STATION

The team at Dukunde Kawa takes a huge amount of care in processing its coffee. All members of the cooperative are trained to only select ripe coffee cherries from their trees.

- On delivery, the cherries are inspected and sorted by hand to ensure only the very ripest cherries are processed. Farmers do the selecting, and receive the highest income from the ripest, healthier fruit. The remainder of their crop still gets purchased by the co-op, at a lower price, to be processed and sold for the internal market.

- Cherry is then sorted by weight using a Pinhalense machine, with any floaters are removed. By using a machine, rather than a clerk, Dukunde Kawa are more transparent with contributing growers about which fruit gets processed. Coffee is then pulped using a mechanical pulper that divides the beans into three grades by weight, with the heaviest, A1, usually having the highest cup quality.

- After pulping, the coffee is pre-washed, graded again using floatation channels that sort the coffee by weight, and left to ferment overnight for around 12–18 hours. The following day, wet parchment is the washed a second time and left to ferment for a further six hours — with the goal of removing as much mucilage as possible without using machinery that may accidentally crush or damage the beans.

- As with most washing stations in Rwanda, women do the majority of hand-sorting. This takes place in two stages – on the covered pre-drying tables and on the drying tables. Washed beans are moved from the wet fermentation tanks onto the pre-drying tables, where they are intensively ‘wet sorted’ under shade for four hours. The idea is that greens (unripe beans) are still visible when the beans are damp, while the roofs over the tables protect the beans from the direct sunlight.

- Next, the beans are moved onto the washing station’s raised drying tables for around two weeks, where they are sorted again for defects, turned regularly and protected from rain and the midday sun by covers, ensuring both even drying and the removal of any damaged or defective beans. During this period the coffee is also turned several times a day by hand to ensure the coffee dries evenly and consistently.

- After reaching 11-12% humidity, the coffee is then transported to Dukunde Kawa’s purpose-built warehouse prior to final dry milling and hand sorting at the cooperative’s milling facilities.

- Located in Ruli, Dukunde Kawa’s dry mill has the capacity to process one full container of coffee a day — and combines the use of technology with meticulous hand sorting to ensure only the best beans are bagged. Before being loaded for export, Rwanda’s National Agricultural Export Development Board also inspects and samples the prepped parchment.

WHY WE LOVE IT

Most of the coffees we source from Rwanda are traceable back to a washing station, or sometimes a farmer group. Typically, washing stations in Rwanda receive cherry from hundreds (and sometimes thousands) of farmers who own very small plots of land – on average less than a quarter hectare, with just 300-600 coffee trees. Separation of such tiny lots is expensive and impractical, so the large majority of coffees are processed as a mixed lot from multiple producers. Lots are separated as day lots (ie. cherries that were all picked on the same day) rather than by a single farm or producer group.

Single farm microlots like this one are difficult to access, especially from such a small-scale producer (Michel owns 541 trees across three plots). In this case, it is made possible because Michel is a member of Dukunde Kawa Cooperative, who have recognised the excellent agronomical practices he follows and consider him a role model to neighbouring farmers. Because the co-op also operate their own dry mill, they can process smaller lots individually, whilst minimising cost and maintaining excellent quality standards. We feel extremely fortunate to be able to share this special lot from Michel Dusengimana and wife Devotha Nyirahabimana. The region where Michel and Devotha grow coffee produces coffees with complex floral notes and a distinct tropical acidity, and their lot is no different, presenting great structure with notes of caramel and apricot jam.