Ruli Anaerobic

Intensely fruit forward and tropical, with tangerine, blueberry and creamed honey. Distinct and complex.

This specially prepared coffee lot was contributed to by some of the 96 smallholder farmers who deliver to Ruli washing station and processed using a natural anaerobic method (or sealed ferment). Ruli is one of three washing stations owned by the Dukunde Kawa Cooperative, located close to the small town of Mususa, in the Ruli Sector or Gakenke District, in Rwanda’s rugged and mountainous Northern Province. Like most coffee from Rwanda, this lot is 100% Red Bourbon.

Ruli sits at 1,920 meters above sea level, overlooking a beautiful landscape of rolling green hills and rich, red earth. A total of 1756 farmers (1104 men, 652 women) deliver cherry to the washing station throughout the season, which employs 36 permanent staff and increases by another 148 seasonal staff during the harvest period. The area surrounding Ruli has mineral-rich soil and a lush environment that is well suited to specialty coffee production. Typically, farms are situated between 1,800 to 2,100 meters above sea level.

The producers who contribute to the Ruli washing station own an average of one tenth of a hectare of land, on which they farm coffee, along with subsistence food crops like maize, beans and sorghum and some livestock like goats and chickens. Cows are also an important asset to a farming family. Besides having practical advantages – like providing milk and yoghurt to feed the family, producing excellent manure for the coffee farms, and being an opportunity for additional income – they are also a traditional symbol of wealth and status in Rwanda.

The washing station was established in 2003 and is the largest of Dukunde Kawa’s washing stations. It serves as the head office for the cooperative’s management team and the site also encompasses the cooperative’s dry mill and its dairy operations. The property is also the site of the Rambagirakawa community room and Dukunde Kawa’s cupping lab, nursery and model farm. Recently, the cooperative decided to expand their business by establishing a commercial roastery that supplies coffee to restaurants and hotels across town, with all activities carried at a building also located in Ruli.

Quality control operations at Ruli are overseen by Emerthe Mukamurigo, who has held this position since 2014, while the day to day is managed by Philomene Nyirabantu. Ruli is Rainforest Alliance certified, UTZ certified, and Fair Trade certified. These certifications help the growing cooperative find different markets for the coffee. “We were already doing a lot of the things that were required for these certifications”, Isaac (the executive secretary of the cooperative at the time) explained, “We are always trying to be the best cooperative we can be. Getting the certifications has helped highlight what we are doing well and helped us raise our standards in other areas.”

Head here to learn more about the work of Dukunde Kawa in Rwanda.

ANAEROBIC PROCESSING AT RULI WASHING STATION

The team at Dukunde Kawa takes a huge amount of care in processing its coffee. For their natural and anaerobic processed coffees, Dukunde Kawa cooperative members are taught to select the heaviest and juiciest coffee cherries, as these are the ripest and have the highest sugar content.

- On delivery, the cherries are inspected and sorted by hand to ensure only the very best fruit is processed. They are then sorted by weight in water (and any floaters are removed) to ensure only the densest cherries are selected.

- After sorting, coffee cherries are placed in oxygen-deprived tanks (this is achieved through candle burning or a distillation process) and hermetically sealed.

- The coffee ferments for a period of 100 hours (around five days), allowing for microorganisms present in and on the cherries to break down sugars and mucilage into complex metabolites, enhancing the acidity, body and overall flavour profile of the coffee.

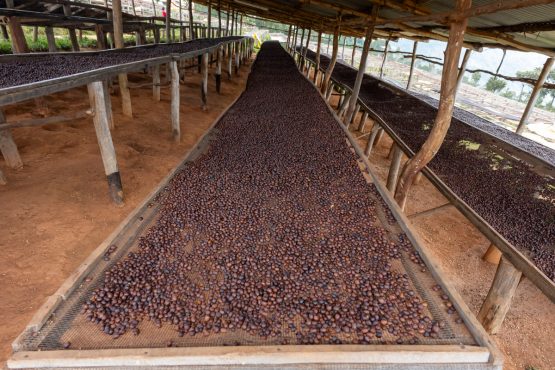

- Once the desired level of fermentation is achieved, cherries are removed and laid out to dry in the sun for about 50-60 days, depending on weather conditions. As coffee dries, it is sorted again for defects, turned regularly and protected from rain and the midday sun by covers, ensuring both even drying and the removal of any damaged or defective beans. During this period the coffee is also turned several times a day by hand to ensure the coffee dries evenly and consistently. As with most washing stations in Rwanda, women do the majority of hand-sorting.

- During the final stages of the drying process, cherries are laid out in raised beds under cover.

- After reaching their target humidity readings, the coffee is then transported to Dukunde Kawa’s purpose-built warehouse prior to final milling and hand sorting at the cooperative’s dry mill.

WHY WE LOVE IT

This lot exemplifies the innovation and hard work the members of Dukunde Kawa have undertaken to produce coffees that fulfil the potential of this beautiful region. We love how distinct and complex this coffee is, with tangerine, blueberry and creamed honey in the cup.

We feel so lucky to work with Dukunde Kawa. When we first started working with the cooperative over a decade ago, the president at the time, Anastase Minani, explained that their goal was to be the very best cooperative in Rwanda. We think they’re well on their way to achieving this goal, and we are excited to have been able to share this journey with them.