Victoria Mukamurenzi

Cherry limeade and black tea with brown sugar sweetness. Transparent, with great structure.

As the Vice-President of Rambagirakawa, Dukunde Kawa Cooperative’s women’s alliance, Victoria Mukamurenzi is an incredibly busy woman. Whenever she’s not tending to her farm, she’s overseeing the Rambagirakawa handicraft shop, or working on the many projects the alliance is involved in. That’s why we are so excited to feature her coffee for another year, after first purchasing it in 2023.

The daughter of farmers, Victoria began working in coffee from a very young age – learning the ropes from when she was just a toddler in the 1980s. She was always passionate about coffee, as she told us on our most recent visit, “I have lived like this since my childhood. My parents were also coffee farmers. I used to go together with my parents to the coffee fields, and I found that coffee is what that made us grow as a family – it was our only source of income.” As she grew up, she became more involved with the farm’s activities until she eventually found job at a coffee nursery, where she would look after seedlings and young coffee trees.

As a child, Victoria saw her parents undertake great effort to grow, process and sell their coffee crop. At this time, coffee production was extremely arduous for Rwandan coffee farmers. Processing was labour-intensive and lengthy, with very little equipment, training or resources available to rural farming communities. Typically, coffee cherries were depulped by hand using stones and parchment was dried at farm level, before being sold to a middleman or ‘broker’ who would then on sell the coffee to traders or exporters based in Kigali. Not only did this result in a long and challenging harvest season for individual farmers, it also denied them any leverage for negotiating prices to achieve a fair and reliable income.

With the forming of cooperatives like Dukunde Kawa, farmers were provided with the support, education and resources necessary to adopt better farming practices, and processing moved to centralised washing stations – where shared infrastructure, equipment and adequate labour both minimised the workload for individuals and dramatically improved the coffee’s quality.

Once married, Victoria and husband Theobald Habineza began to take care of land he had inherited from his parents. Because coffee was already planted, Victoria knew if they put their minds into it, they could expand the plantation and earn an income from coffee, as her family had when she was growing up. In 2002, her husband got a job at a construction site near their home — which turned out to be Dukunde Kawa Cooperative’s Ruli washing station. Victoria’s husband became a member and started working for the co-op on a full-time basis after the building was complete, and the pair have been closely linked to Dukunde Kawa ever since.

In 2010, when the cooperative was sourcing handwoven baskets, they reached out to Victoria, who was known to be a maker and seller of handicrafts. After she sold some of her stock to Dukunde Kawa, she brought up the idea that, rather than sourcing baskets from outsiders, they should be teaching members how to make them so that the co-op could produce their own baskets, because this could create an opportunity for additional income. After this interaction, Victoria joined Dukunde Kawa the following year.

Becoming members of the co-op has been empowering for the couple, as they have earned fair and reliable prices for the coffee they farm together, as well as received training in financial literacy, gender equality, coffee farming and market access. In 2012, when the cooperative founded Rambagirakawa women’s group, Victoria was one of the first members to join. A savvy and entrepreneurial woman, Victoria’s idea of teaching fellow Rambagira members to weave baskets and handicrafts was well-received by the group — particularly by her neighbour and Rambagirakawa founder Odette Murekatete. The pair already knew each other from attending the same church, but as they began to work more closely at the co-op, they became inseparable.

Today, Victoria and Odette never go more than a couple of days without seeing each other, and basket weaving is one of Rambagirakawa’s main income-generating activities. Victoria’s leadership within the group was recognised when she was named Vice-President of Rambagirakawa. In this role, she assists in the managing of the group’s finances, liaises with Dukunde Kawa’s leadership on behalf of the group, and develops projects to benefit the women who form part of the alliance. Joining the women’s alliance has been particularly transformative for Victoria, as she recently told us, “Before I joined the cooperative and Rambagirakawa specifically, even my thinking was limited. My ability to think beyond the box was limited.” Now, she can be found at the Rambagirakawa house in Ruli washing station every day, sewing her baskets and making sure all members of the alliance have the support they need.

As Victoria got more involved with the co-op, who were heavily promoting women’s coffee lots, she brought up the idea to her husband and decided to establish her own plot of land. Initially, she tended to a selection of trees already established — but in 2018, using knowledge she had gained working with coffee for many years, and with the advice of Dukunde Kawa’s team of agronomists, she established her own nursery at home, using seedlings that had grown from cherries she had harvested herself. Her first harvest arrived in 2023, producing some 200kg of cherry — which had tripled by 2024! Husband Theo reckons the venture has been a success for the family, recently telling us, “I’m happy that she is part of that bigger community, because she’s bringing back that knowledge. She’s bringing back new things; she’s bringing back that enlightenment. And that’s part of the improvement we find here. If something is good and it works, you have to support it.“

Operations at the farm are methodical and precise, as taught by Dukunde Kawa’s agronomists. During the harvest, only the ripest cherries are selected and great care is taken to ensure young branches aren’t damaged — as these are more likely to flower at the start of the new crop. Once cherry has been picked, trees are tidied to remove any withered or weak branches, which helps determine which ones are ready to be pruned. The discarded plant material is also used to create mulch on the farm’s soil, a necessary addition that helps plants retain moisture during the dry season.

With the income generated from coffee, Victoria and Theobald have made improvements to their home, where they live with their three children. The eldest, Diane, is a university student who lends a hand during her holidays, while the younger siblings (a pair of twins, Delphine and her brother) are finishing their secondary studies. Victoria’s goal this year is to plant another 150 trees, to gift to her daughters. She hopes they then become cooperative members themselves, as part of Dukunde Kawa’s youth programs. Farming is already a family affair, to Theobald’s delight, who shared with us in 2024 that he feels “really proud for my family because they are willing to join me in my activities. They are very good workers. We meet together in our purpose.” At the property, the family have planted crops like soghurm, yams, bananas and papaya, and raise rabbits and pigs alongside their cow. The crops held add mulch and shading to the farm, and the produce is either consumed or sold for profit at the local market.

When we asked Victoria if she had a message for the Australian community who enjoys her coffee, she told us, “As they really show love by liking and buying the coffee, we keep putting in effort to maintain the quality. We ask them to be our ambassadors, so that we can expand the market. If you have time to come and visit us, it really makes us strong – like we are not wasting our efforts.”

ABOUT RULI WASHING STATION

Ruli washing station was the first site established by Dukunde Kawa, back in 2003. It remains the main centre of operations for all of the cooperative’s activities, serving as the head office for the cooperative’s management team, who can often be seen buzzing about the property during the harvest.

In addition, the site is home to the Rambagirakawa Women Alliance’s community building and the newly-built Musasa Early Childhood Development Centre (Musasa ECDC), along with Dukunde Kawa’s cupping lab, nursery and model farm. Recently, the cooperative decided to expand their business by establishing a commercial roastery at Ruli, that supplies coffee to restaurants and hotels across town. Because the washing station is so central, Dukunde Kawa have also opened a café here, which sells the co-op’s coffee and locally baked goods. Recognising it has potential to service many members of the community, the cooperative is also hoping to establish their own bakery, to be run by youth who are part of the co-op.

Ruli is also where Dukunde Kawa’s dairy is located. Over the years, Dukunde Kawa have provided many of their member farmers access to their own cows, which are an important asset to a farming family. Culturally, they are seen as a symbol of wealth and status in Rwanda; practically, they provide milk and yoghurt to feed the family, produce excellent manure for the coffee farms, and create an opportunity for additional income. Having recently upgraded their largest pasteuriser from a 500L machine to one that can process 5,000L, Dukunde Kawa have been able to expand their operations at the dairy factory and take on a contract with a distributor who works throughout all of Rwanda and its neighbouring countries.

Over 2,000 farmers deliver cherry to the washing station throughout the season. Quality control at Ruli is overseen by Emerthe Mukamurigo, who has held this position since 2014, while day to day operations are managed by Philomene Nyirabantu, who has been a co-op member and part of Ruli’s full-time staff since 2004. In the twenty years she has been employed by the cooperative, Philomene has worked both as a drying officer at Ruli and as a field officer (she completed her studies as an agronomist in 2011), supporting member farmers in improving the quality and volume of their crop. Since 2022, Philomene has managed production at Ruli, earning the title of Station Manager in 2025.

During the harvest, Philomene is assisted by Dative Niyifasha, who supervises sorting and drying. There are a whopping 250 drying beds at Ruli, which require constant oversight. Dative has also been a cooperative and staff member since 2004, having transitioned from working with farmers on the field in 2017 to become a drying officer at Ruli. Both Philomene and Dative deliver coffee to be processed at Ruli and are members of the Rambagirakawa Women’s Alliance (Dative’s youngest is also a student at Musasa ECDC). The pair manage Ruli’s team with positivity and confidence — the pace at a processing site of this size can be relentless during the peak of the harvest — relying on their two decades of experience with Dukunde Kawa to continually encourage the washing station’s staff.

Ruli is Rainforest Alliance certified, UTZ certified, and Fair Trade certified. These certifications help the growing cooperative find different markets for the coffee. “We were already doing a lot of the things that were required for these certifications”, Isaac (the executive secretary of the cooperative at the time) explained, “We are always trying to be the best cooperative we can be. Getting the certifications has helped highlight what we are doing well and helped us raise our standards in other areas.”

Head here to learn more about the work of Dukunde Kawa in Rwanda.

PROCESSING AT RULI WASHING STATION

The team at Dukunde Kawa takes a huge amount of care in processing its coffee. All members of the cooperative are trained to only select ripe coffee cherries from their trees.

- On delivery, the cherries are inspected and sorted by hand to ensure only the very ripest cherries are processed. Farmers do the selecting, and receive the highest income from the ripest, healthier fruit. The remainder of their crop still gets purchased by the co-op, at a lower price, to be processed and sold for the internal market.

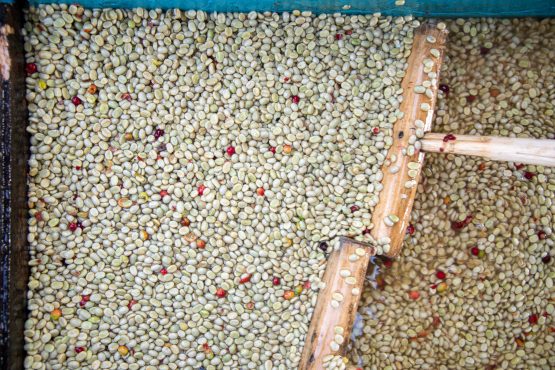

- Cherry is then sorted by weight using a Pinhalense machine, with any floaters are removed. By using a machine, rather than a clerk, Dukunde Kawa are more transparent with contributing growers about which fruit gets processed. Coffee is then depulped using a mechanical pulper that divides the beans into three grades by weight, with the heaviest, A1, usually having the highest cup quality.

- After pulping, the coffee is pre-washed, graded again using floatation channels that sort the coffee by weight, and left to ferment overnight for around 12–18 hours. The following day, wet parchment is the washed a second time and left to ferment for a further six hours — with the goal of removing as much mucilage as possible without using machinery that may accidentally crush or damage the beans.

- As with most washing stations in Rwanda, women do the majority of hand-sorting. This takes place in two stages – on the covered pre-drying tables and on the drying tables. Washed beans are moved from the wet fermentation tanks onto the pre-drying tables, where they are intensively ‘wet sorted’ under shade for four hours. The idea is that greens (unripe beans) are still visible when the beans are damp, while the roofs over the tables protect the beans from the direct sunlight.

- Next, the beans are moved onto the washing station’s extensive raised drying tables for around two weeks, where they are sorted again for defects, turned regularly and protected from rain and the midday sun by covers, ensuring both even drying and the removal of any damaged or defective beans. During this period the coffee is also turned several times a day by hand to ensure the coffee dries evenly and consistently.

- After reaching 11-12% humidity, the coffee is then transported to Dukunde Kawa’s purpose-built warehouse prior to final dry milling and hand sorting at the cooperative’s milling facilities.

- Located in Ruli, Dukunde Kawa’s dry mill has the capacity to process one full container of coffee a day — and combines the use of technology with meticulous hand sorting to ensure only the best beans are bagged. Before being loaded for export, Rwanda’s National Agricultural Export Development Board also inspects and samples the prepped parchment.

WHY WE LOVE IT

Most of the coffees we source from Rwanda are traceable back to a washing station, or sometimes a farmer group. Most washing stations in Rwanda receive cherry from hundreds (and sometimes thousands) of farmers who own very small plots of land – on average less than a quarter hectare, with just 300-600 coffee trees. Separation of such tiny lots is expensive and impractical, so the large majority of coffees are processed as a mixed lot from multiple producers. Typically, lots are separated as day lots (ie. cherries that were all picked on the same day) rather than by a single farm or producer group.

Single producer microlots like this one are not very common in Rwanda. While Victoria’s farm is small (she owns 153 trees), she benefits from being a member of the Dukunde Kawa Cooperative, who have recognised the excellent agronomical practices she follows and consider her a role model to neighbouring farmers. Because the co-op also operate their own dry mill, they can process smaller lots individually, whilst minimising cost and maintaining excellent quality standards. We feel extremely fortunate to be able to share this special lot from Victoria Mukamurenzi’s farm Kinyonzo-Jango. This is the third time that we have purchased Victoria’s coffee, and we are excited to continue working with her in the future and as she grows her farm further. This lot is transparent and well-structured, with brown sugar sweetness added notes of cherry limeade and black tea.